CarMax Capture App

In 2018, CarMax had started installing indoor photo studios across their 150+ retail dealerships. These photo studios were built with efficiency and cost savings in mind; the assumption being that instead of sending a car to sit outside on the lot to eventually be photographed and merchandised, it could now go straight from the repair and reconditioning line to the photo studio.

However, the reality proved that realizing these efficiencies were far greater than initially assumed. As photo studios started to come online, the time to get a car prepped for selling dramatically increased.

"CarMax transforms the merchandising of a CarMax Car through the use of AI computer vision, automated machinery, and deep user research."

-Vision Setting PR Headline

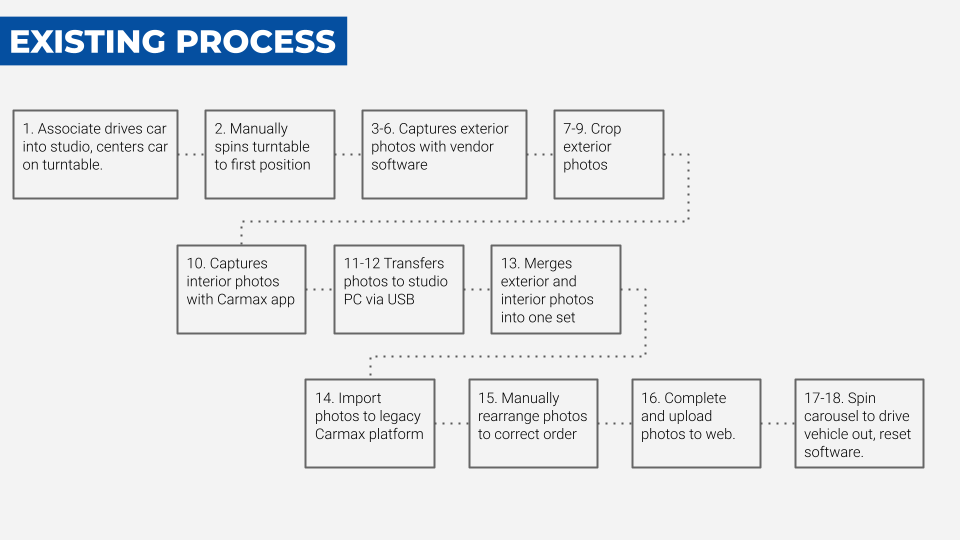

The culprit: third party software

My team was responsible for investigating and solving the slow pace times that stores were experiencing. I started by gathering both quantitative (pace time metrics) and qualitative (observation) data. The data quickly pointed towards the third-party software that controlled the carousel and camera as the major limiting factor. The software was an off-the-shelf solution intended for professional photographers on a much smaller scale. Within the context of a fast-paced retail operation, the software was cumbersome, difficult to train, and prone to error-out when communicating with the turntable and other machinery inside the studio.

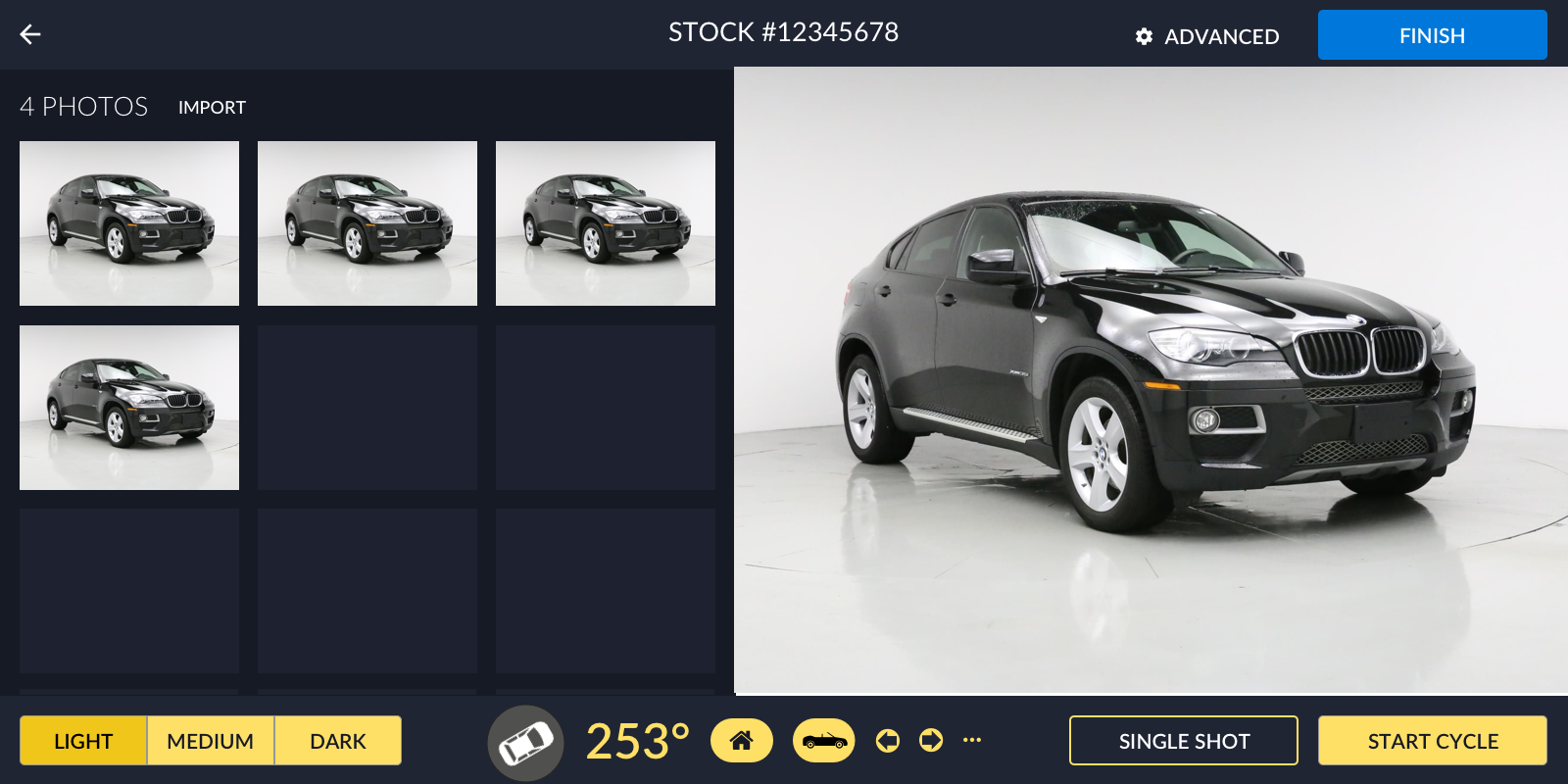

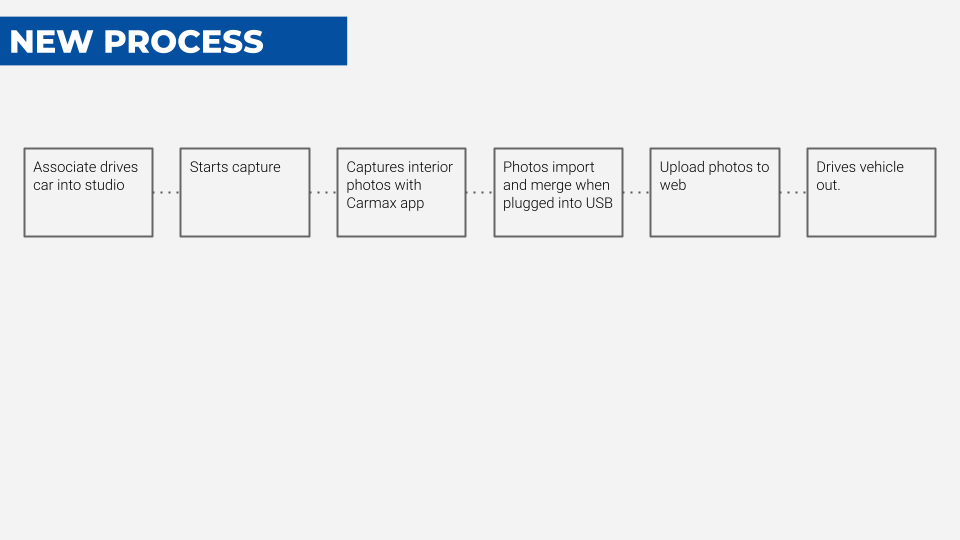

The solution: CarMax Capture

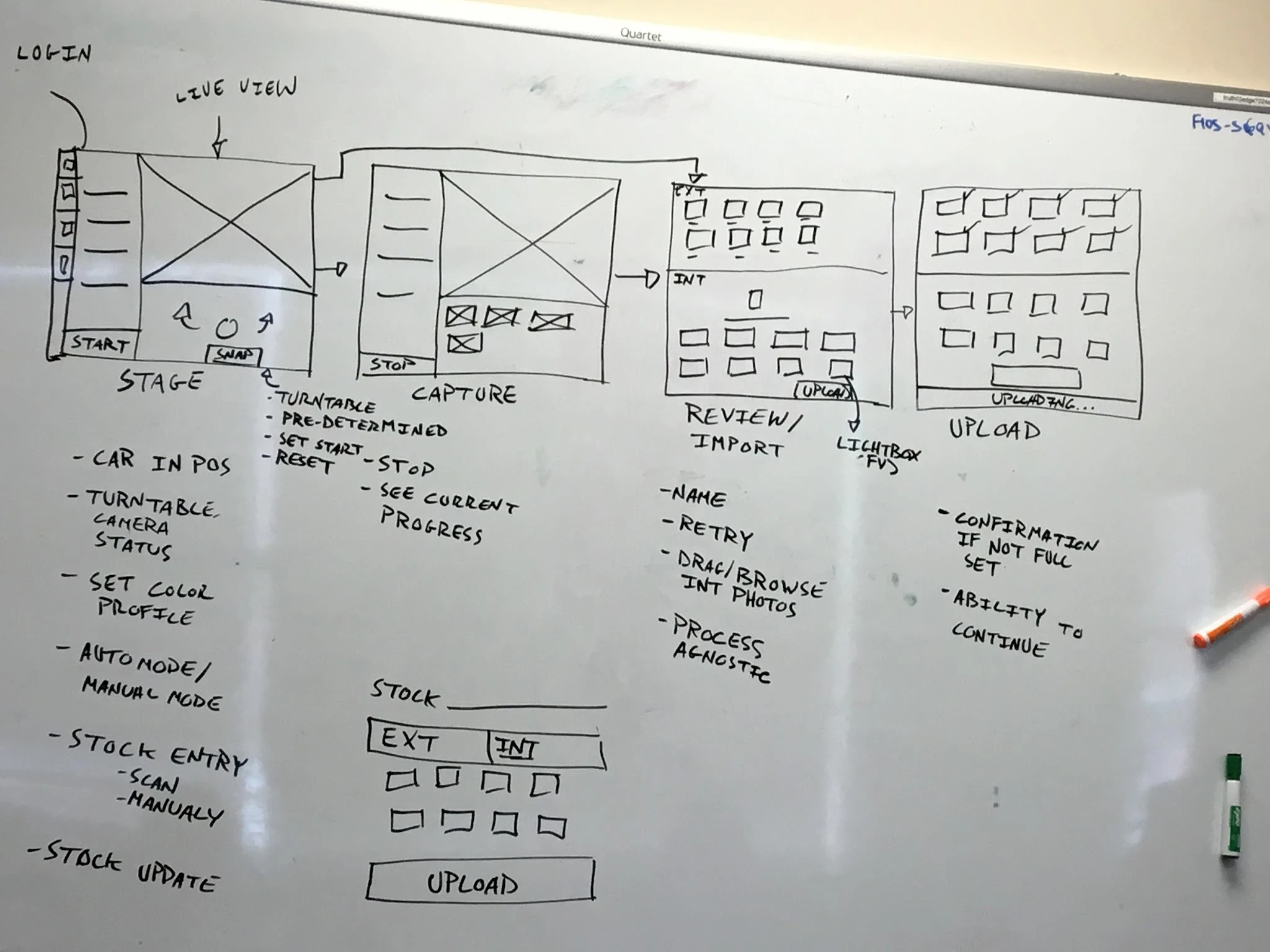

I knew we could do better, so my team and I decided we would design and develop our own custom studio software from the ground up. My pitch to stakeholders was to give myself, a software engineer, and a product manager a few weeks, and we would have working software that could be tested at one of the stores challenged by the existing solution.

Using AI to turn associates into pro photographers

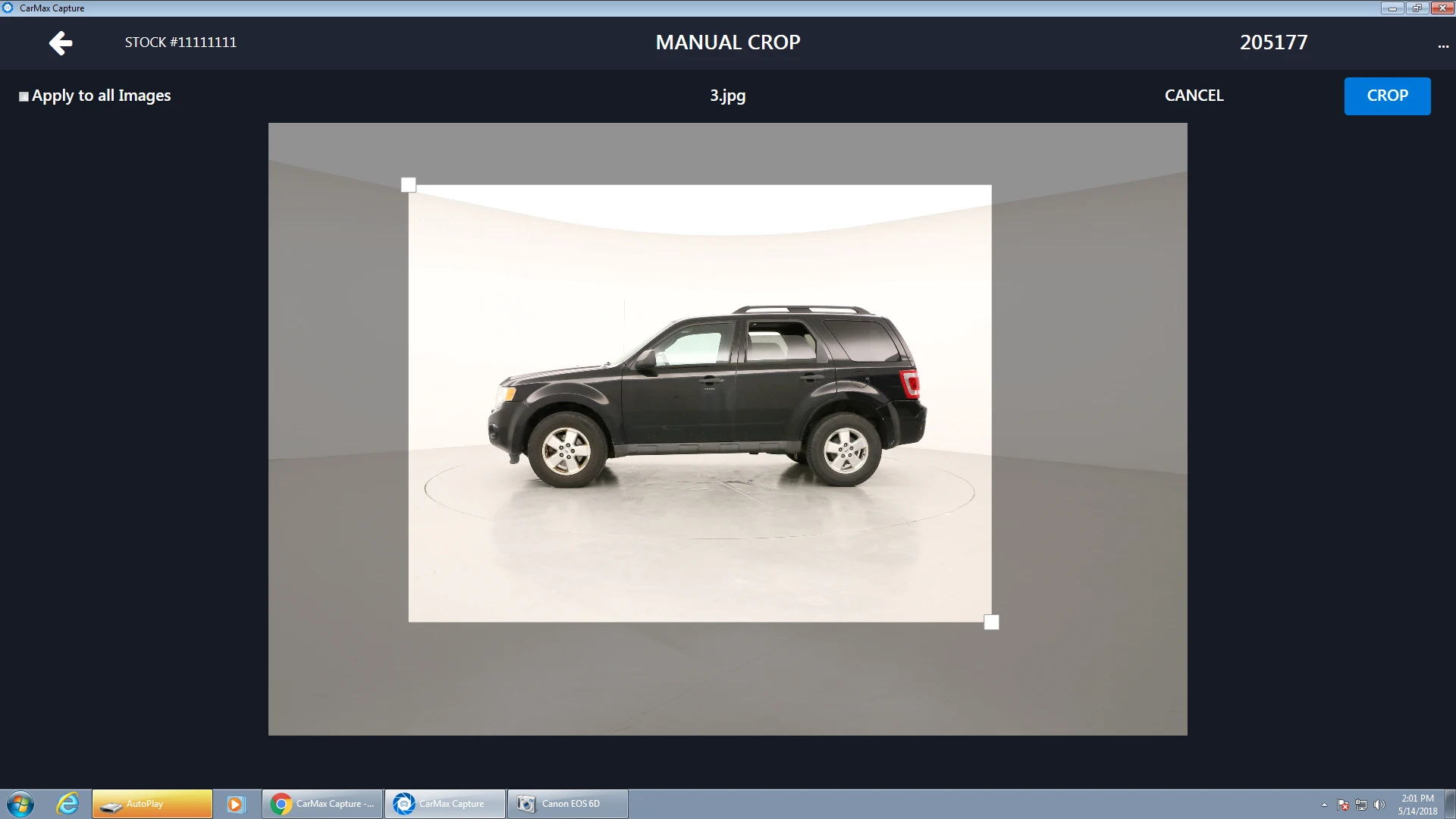

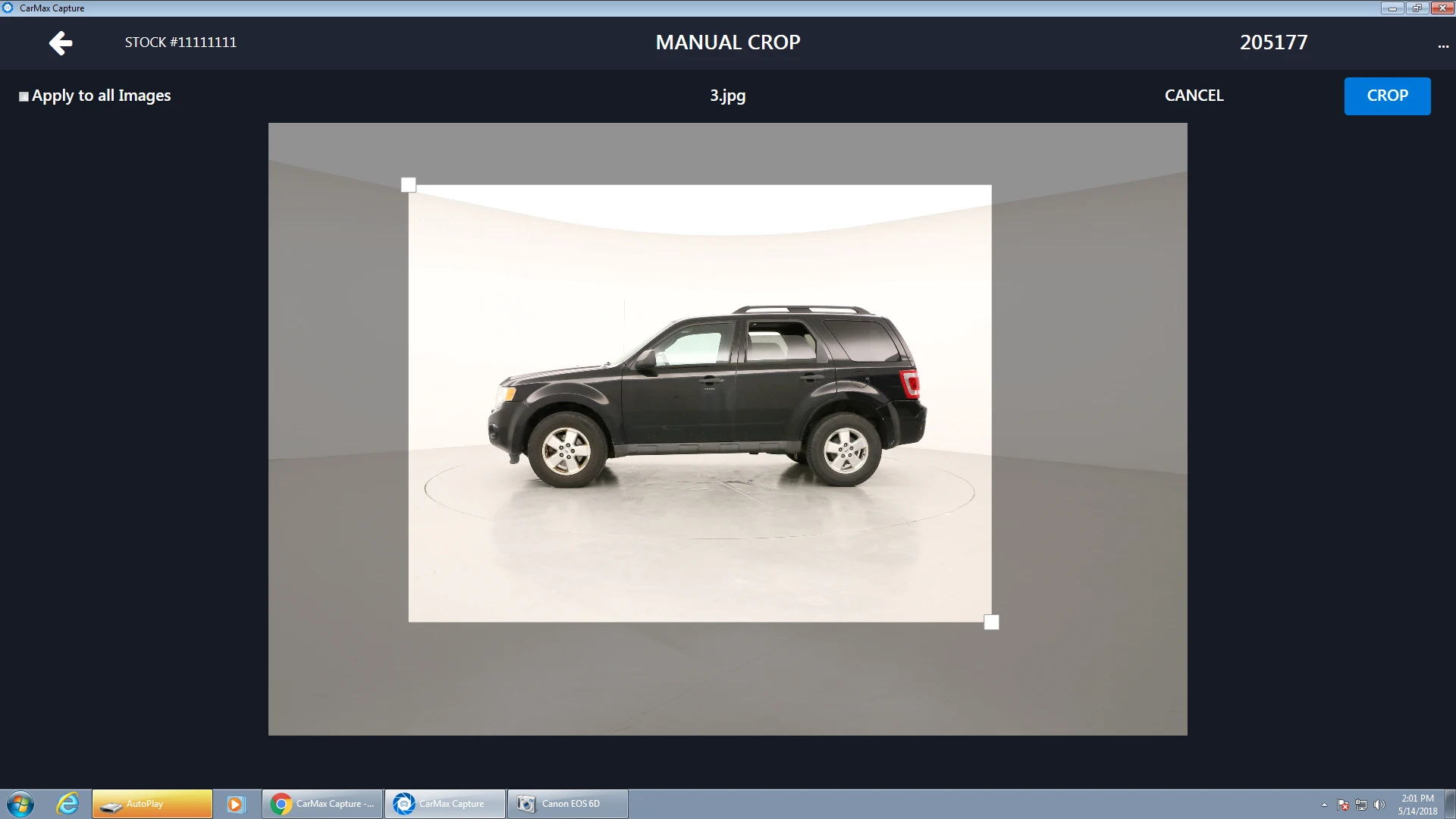

The first thing I did was get the team out of our air conditioned office building and in the field, where the problems were happening. I took the lead engineer on my team to a nearby CarMax store with an indoor photo studio, and began to talk to the associates on which parts of the process were the most difficult and important to accomplish. By collaborating with the end-users, we quickly realized how we could use technology and design to solve the most difficult parts of the process. For example, cropping pictures of a car correctly was very difficult for associates. Associates had to be taught how to apply a crop a photo of a car, and the photo-editing software to create the crop was not user-friendly. In collaboration with the lead engineer on my team, we built a solution that used a machine-learning algorithm to apply a “recommend” crop to a photo, with controls to make final-adjustments.

The machine-learning algorithm used training data from our own inventory of car pictures, allowing us to tune the model to fit our use case. With this one improvement alone, we were able to dramatically improve the overall task success and time to completion.

From paper prototype to working software

Instead of waiting until the end of a design cycle to engage end-users, I made it a goal in this project to involve the associates who would be using this software from day 1. I facilitated what I called “co-creation sessions” to rapidly ideate and prototype new concepts with the software with actual associates, often while they worked their shift. I built relationships with store managers and operations engineers to get buy-in, and analyzed which stores would be most willing to be the early-adopters for our new software and process. Because of this work, our team was able to go quickly from paper-based prototypes to working software in just a few sprints.

Rollout and the evolution of CarMax Capture

After proving that the custom software was working and getting positive feedback from our test store, we got the green-light to expand to the rest of the stores. Our team spent a few more sprints hardening the software and tweaking the process before we handed the project over to our partners in operations to fully productionalize what we had built. Our primary metric, time to merchandise a vehicle, showed a dramatic improvement and a significant increase in profit per unit. But for me, I was most happy to see how positive the feedback was from the associates who were using the software. Our relationships and reputation with the field became stronger, which allowed us to continue to experiment and try new things in the field. I continued research, and found overwhelming evidence that the new process was dramatically preferred over the old way.

And thanks to our work in AI and computer vision, CarMax was able to further enhance the merchandising experience for years to come. Interactive hotspots and other immersive experiences were later added to the software, experiences that otherwise would have been impossible to create without deeply reimagining how associates would interact with the tool.

Selected Works

CarMax Capture AppProject type

Docusign Joint AgreementsProject type

Case study: bringing 360° photography to CarMaxProject type

AI Agreement Comparison PrototypeProject type